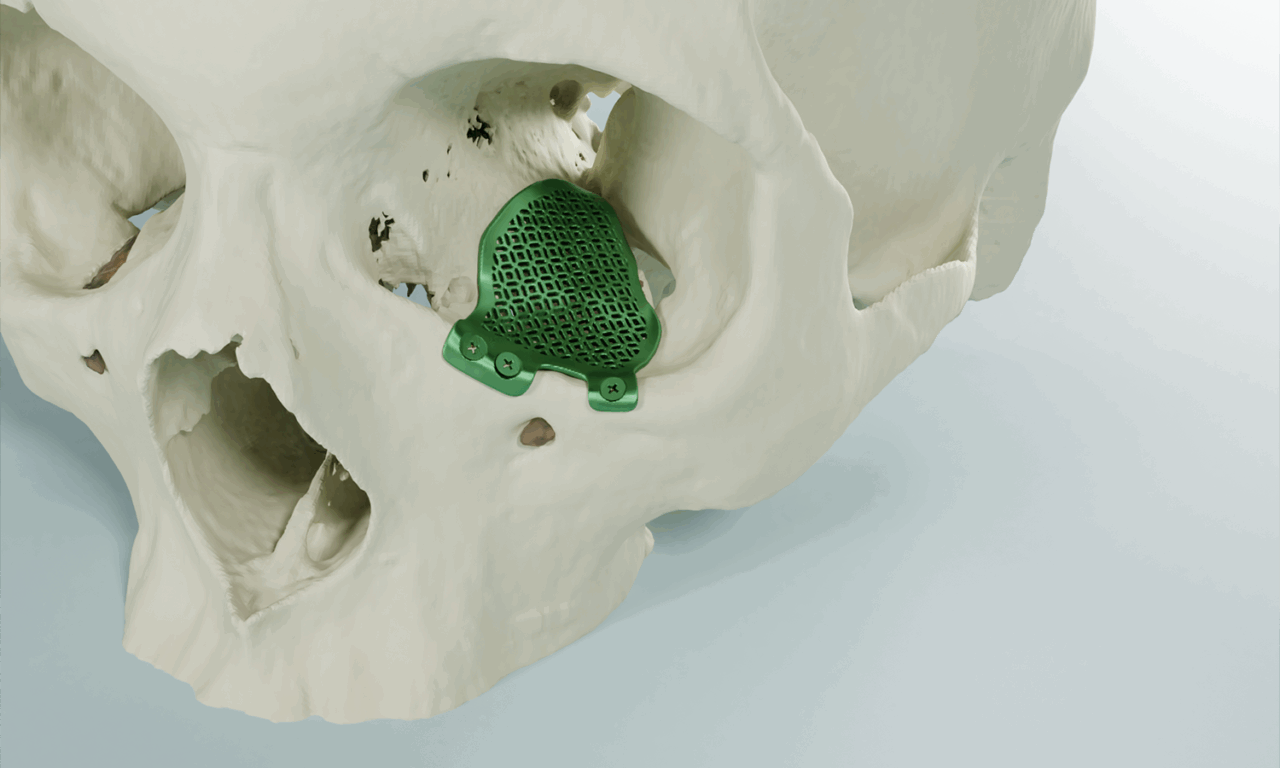

AccuPlan® & AccuPlate®

CMF Reconstruction

Overview

Comprehensive Virtual Surgical Planning and Patient-Matched Implants

AccuPlan and AccuPlate work to optimize maxillofacial and orbital reconstruction surgeries using detailed patient scan data and surgeon input. Our AccuPlan surgical planning uses 3D-CAD software to design custom guides, splints, and models, and AccuPlate delivers 3D printed titanium plates for a patient’s unique anatomy, customized for screw hole placement, thickness, and contour. Our advanced 3D printing allows for intricate designs that reduce mechanical stress and ensure precision in complex reconstructions.